The Importance Of Using Proper PSI For Air Tools

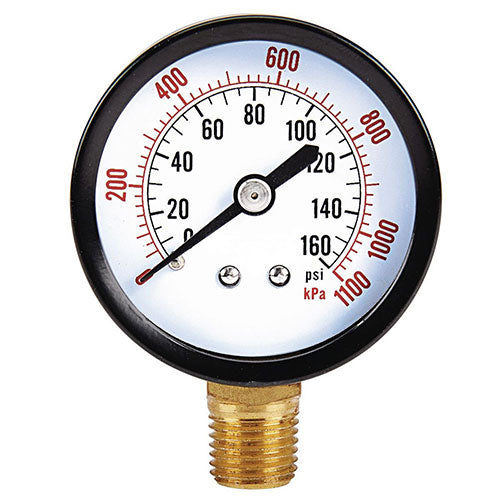

Be honest. Do you use too much air pressure in your air tools? More PSI means more power, right? Well, it may produce a short-term burst in power sometimes, but it almost always leads to tool breakage or worse. Here are four key reasons to always use the proper pressure for your air tool.

Save Money On Expensive Repairs:

Using too much pressure can cause your air tools to wear out or break a lot sooner than they should. Here are some of the most common pneumatic tool repairs caused by excessive air pressure:

Blown seals: The more pressure you use, the bigger the opportunity for blown seals.

Anvil breakage: You may think, “I can just apply more pressure to my impact wrench to get more torque, so the job gets done faster.” More pressure puts increased stress on the anvil which can crack or break, and then your tool is down for repairs. That time you saved goes out the window and cash for repairs will be coming out of your pocket.

Bearing failure: In addition to blown seals and anvil breakage, using too much pressure is one of the most direct causes of bearing failure. Bearing failure is an expensive repair and if the bearings go, get ready for many more damaged parts to repair.

Vane motor breakdowns: As little as 20 psi of extra pressure in a vane motor system can reduce the life of an air tool by half. Most tools are rated at 90 or 100 psi, so using 120 psi regularly means you will be replacing expensive air tools in half the time.

Maintain Tool Efficiency:

Air Tools don’t usually break in an instant. More often they wear down over time and die. When air tools start wearing down, the seals and other components start losing efficiency. Even if the tool does somehow keep working, you’re going to be pumping more air than you normally would to keep it running. The message is simple: Use the right pressure. Maintain your tool regularly. Get top performance on your investment.

Prevent Dangerous Accidents:

Pressure safety warnings exist for a reason. Not following them can cause serious injury, or even death. You may shrug it off and say, “That will never happen to me.” Well, it happens to people. And if it does happen to you, a co-worker, an employee, or a friend, well, it’s something you don’t want to even imagine. Be safe. Always.

Lower Fuel Consumption:

Finally, using proper pressure lowers fuel consumption. The higher the pressure, the higher volume of air that’s used. Running your tools higher than the recommended pressure requires more energy which means you are spending a lot of extra horsepower on wasted air. Save some money on operating costs and keep your emissions under control by lowering fuel consumption.

In Conclusion

Using too much pressure for your air tools can be costly in so many ways. From equipment failure and repair costs to health and potential safety risks. There are countless reasons to use the proper air pressure. It’s easy, makes sense and ultimately will save you money and a whole bunch of headaches.